#ETAuto #StartupAdda Episode 18- Cygni Founder & CEO, Mr. Venkat Rajara “How this startup is solving the hurdles of mass adoption of li-ion batteries? “

“EV Decade is here and Batteries will be pivotal in India’s EV transition” article has published on Energetica India Magazine .

Li-ton Battery Technology:

Battery technology is progressing on several fronts. On the Energy Cost, the trend is moving away from Cobalt, due to cost and safe mining concerns. Removing C (Cobalt) from NMC (Nickel-Manganese-Cobalt) chemistry has been a key focus of research. The energy density is also improving with NMC111 to NMC532 to NMC811.

Read here: Energetica

On The Economic Times for publishing, “Efficient solar-storage hybrid solutions are the need of the hour” insights by the emerging leader, Mr. Venkat Rajaraman .

Ambitious goals, concerted strategies, and a collaborative approach could help India meet its emission reduction targets while avoiding import dependency for battery packs and cells. This could help establish India as a hub for cutting-edge research and innovation, boost its manufacturing capabilities, create new jobs, and foster economic growth.

Read here: Economic Times

On Energetica Magazine October- November Edition showcasing insights of the Mr. Venkat Rajaraman & Ravikumar Gurumurti – “Are Batteries Enough to Fulfill the Industry’s EV PROMISES?”.

Hyderabad- Battery quality and its ability to deliver on all the parameters critically depend on the quality of cathodes, anodes and other critical components. With very little entry barrier, many of the components available in the market can not be trusted for its quality. Sourcing components from tier-1 suppliers amidst rising demand would pose serious procurement challenges.

Read here: Energetica Magazine

We are happy to share that the coverage which has featured on the first page of Telangana Today newspaper, print. The coverage has also appeared in online edition as well.

Hyderabad: The Electric Vehicle policy of the State government has so far attracted Rs 5,600 crore worth of investment and generated 3,800 jobs 2013 both direct and indirect. Many large and small companies have chosen the State to set up their manufacturing unit, thanks to the government’s EV policy rolled out in 2020.

Read more

An Article by Mr. Venkat Rajaraman and Dr Mayank Vyas, Lithium Battery experts at Cygni Energy in EVreporter.

India is on the cusp of EV adoption. Battery failures can appear suddenly, and without warning, with the potential of severe injuries, product recalls, and loss of reputation. Hence the EV industry must invest in good battery design with advanced battery intelligence that can predict and prevent the user from unsafe batteries before they lead to any untoward incident. When it comes to Lithium-ion batteries, an ounce of prevention is far better than a pound of cure!

Read more

An Article by Mr. Venkat Rajaraman – Chief Executive Officer, Cygni Energy Pvt Ltd in JMK Research & Analytics,

The safety of Lithium-Ion battery is paramount and historical failures in smartphones and laptops give us valuable insight into the criticality of this issue. It is necessary to develop software intelligence to predict battery degradation, alert users to unsafe batteries and thus avoid any untoward incidents. Achieving this intelligence and 100% battery safety is a business priority now.

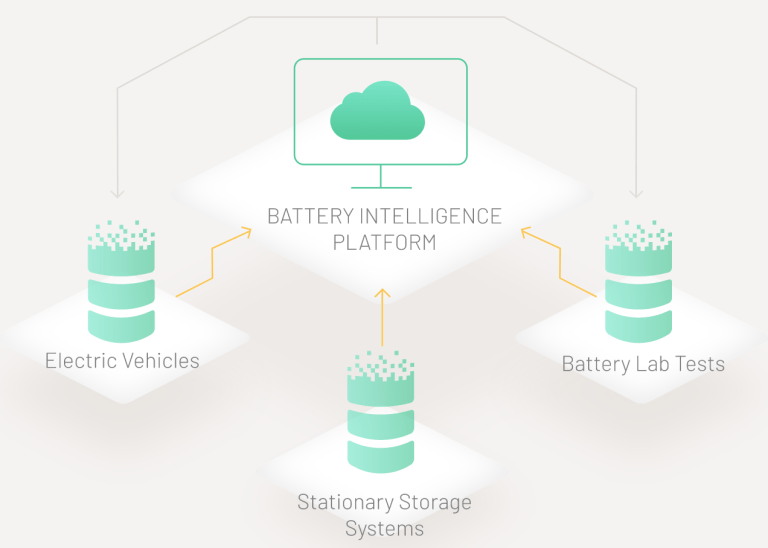

Then Versus Now: The traditional lead-acid battery is an electro-chemical device that is mostly unintelligent energy storage equipment. The battery intelligence is predominantly built around the Inverters or UPS that interface with the lead-acid battery. With the advent of the Lithium-Ion battery, this narrative has completely changed. With its Smart Battery Management System (BMS), the Li-Ion battery relies quite heavily on battery data for battery intelligence, analysis, and safety.

Opinion piece by Venkat Rajaraman – Chief Executive Officer, Cygni Energy Pvt Ltd

Prof Jeff Dahn’s (Dalhousie University, Canada) seminal paper, which got published after 3 years of extensive research, is touted as the “Benchmark for New Battery Technologies”. Though this paper does not describe any brand new chemistry, it is a composite of the industry’s best practices. The secret sauce is the electrolyte, with novel additives and other changes that can make the battery last longer. The paper also focuses on single crystal cathode (powder of cathode material made into a single crystal so that it doesn’t react with the surrounding electrolyte) as well as the best of cathode, anode and electrolyte materials to set the bar for achieving a million-mile battery.

Newsletter

Newsletter DEXTER Board

DEXTER Board